Understanding Agricultural and Forestry Supply Chains: Key Insights and Best Practices

In today's interconnected world, supply chains form the backbone of industries, ensuring that products reach consumers in a timely and cost-efficient manner. Agricultural and forestry industries are no exception, with their own unique logistics challenges and considerations.

Types of Agricultural and Forestry Supply Chains

The supply chain in agriculture and forestry typically involves the movement of raw materials—whether crops, livestock, timber, or other natural resources—from the farm or forest to the market or processing plants. The types of supply chains in these sectors can generally be categorized into the following:

Agricultural Supply Chains: This type involves the flow of food and other crops from farms to distributors and then to consumers or processing facilities. These include:

● Grain supply chains (e.g., wheat, corn, rice)

● Perishable goods supply chains (e.g., fruits, vegetables, dairy)

● Livestock supply chains (e.g., cattle, poultry)

● Organic farming supply chains (focused on non-GMO, pesticide-free crops)

Forestry Supply Chains: These focus on the processing and transportation of timber, paper, and other wood products. Key stages include:

● Harvesting: Extracting wood from forests, either through clear-cutting or selective logging.

● Transportation: Moving logs from forests to sawmills or other processing facilities.

● Processing and Distribution: Turning raw timber into products like lumber, paper, and furniture, which are then distributed to consumers or manufacturers.

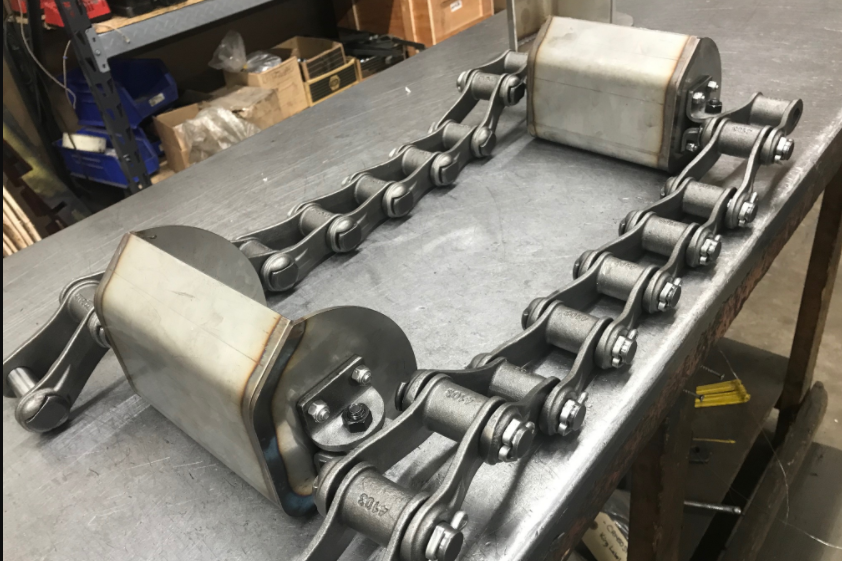

For both agricultural and forestry sectors, the C55 chain and C188 chain are commonly used for specific machinery and equipment involved in these industries. These chains are designed to handle heavy-duty applications, providing reliability and durability in transportation and processing activities. Additionally, agricultural conveyor chains are widely used in agricultural facilities for the efficient movement of crops, such as grains, within warehouses, silos, or processing plants. Similarly, grain drag conveyor chains are an integral part of grain handling systems, helping to transport grains smoothly and efficiently from one point to another.

The type of supply chain a business chooses depends on several factors, including the nature of the product, geographic location, market demand, and available infrastructure.

Choosing the Right Supply Chain for Agriculture and Forestry

Selecting the right supply chain is critical for maximizing efficiency, reducing costs, and meeting consumer demand. Here are a few considerations to help businesses make the best choice:

● Product Type: Different products require different types of logistics. For example, perishable goods need supply chains that minimize time between harvesting and consumption, ensuring freshness and quality. Non-perishable items, like grains or timber, can be transported more flexibly.

● Geographic Location: If you're in a rural area, transportation costs might be higher due to longer distances and less-developed infrastructure. In such cases, the supply chain needs to account for these challenges to avoid bottlenecks.

● Supply Chain Complexity: A more complex product (e.g., organic food or specialty timber) may require a more intricate supply chain, involving more stakeholders and a higher level of coordination.

● Sustainability: Many modern agricultural and forestry businesses are focusing on sustainable practices. This includes ensuring that supply chains reduce carbon footprints, minimize waste, and use environmentally friendly practices throughout.

Choosing the appropriate chains, like the C55 Cast Combination Chain for robust heavy-duty tasks or the C188 Combination Chain for more specialized applications, can help improve supply chain efficiency by ensuring the right machinery is in place for the right tasks. In agricultural processing, selecting the right agricultural conveyor chain or grain drag conveyor chain can streamline the movement of products, reduce delays, and improve operational efficiency.

Daily Maintenance and Care of Supply Chains

Once a supply chain has been established, its efficiency and longevity depend on continuous monitoring and maintenance. Here are some best practices for keeping supply chains running smoothly:

Regular Equipment Inspections

In both agriculture and forestry, equipment used for harvesting, transporting, and processing is subject to wear and tear. Scheduled inspections can prevent unexpected breakdowns and extend the lifespan of machinery. For example, regular checks of the 907E-51 chain in processing machinery and the C55 Cast Combination Chain in logging operations can prevent wear and ensure reliability in heavy-duty applications.

Monitoring Storage Conditions

For perishable agricultural products, maintaining optimal storage conditions (e.g., temperature control for fruits, humidity for grains) is essential to avoid spoilage or loss in quality.

Transportation Checks

Maintaining vehicles (trucks, ships, etc.) involved in transportation is crucial. Ensuring that they are in good working condition, with regular oil changes, tire checks, and inspections of brakes and cargo holds, is vital to avoid delays and damage to goods.

Common Problems in Agricultural and Forestry Supply Chains—and Their Solutions

Despite careful planning and maintenance, problems are bound to arise. The key to a resilient supply chain is being prepared for these challenges and having strategies in place to resolve them quickly.

▶ Issue: Transportation Delays

▶ Solution: Build a buffer into delivery times to account for potential delays due to weather, traffic, or breakdowns. It's also beneficial to have multiple transportation options available to ensure flexibility.

▶ Issue: Poor Harvest Yields

▶ Solution: Collaborate with farmers and foresters to implement better crop management practices, such as crop rotation, soil enhancement, and pest control, to improve yield consistency. Using data-driven forecasting tools can also help anticipate potential shortfalls.

▶ Issue: Supply Chain Disruptions

▶ Solution: Diversifying suppliers and routes is a good strategy to mitigate risks. During times of crisis (e.g., a natural disaster, global pandemic), having contingency plans such as alternative suppliers or local sourcing options can prevent significant disruptions.

▶ Issue: Quality Control Issues

▶ Solution: Setting strict quality standards and performing regular audits at each stage of the supply chain—from farming and logging to transportation and processing—helps ensure that goods meet the required specifications. Additionally, ensuring that chains like the C188 chain or 4103 chain are maintained properly can help prevent quality issues related to machinery failures.

▶ Issue: Labor Shortages

▶ Solution: The agricultural and forestry industries often face seasonal labor shortages. By investing in automation where feasible, offering incentives, and training local workers, businesses can mitigate labor-related challenges.

Friendly Reminder

Agricultural and forestry supply chains are critical components of the global economy, ensuring that essential products reach consumers and businesses efficiently. Choosing the right supply chain, maintaining equipment, and addressing common challenges are all vital to ensure the smooth flow of goods from farm or forest to market. By understanding these processes and implementing best practices, businesses can optimize their operations, improve profitability, and better meet the needs of their customers.

Whether you're involved in growing crops, managing forests, or processing raw materials, a solid supply chain strategy will set you up for long-term success in these dynamic industries. Using the right chains—like the C55 Cast Combination Chain, C188 Combination Chain, 907E-51 chain, 4103 chain, agricultural conveyor chain, and grain drag conveyor chain—ensures that the machinery involved in these processes operates effectively and efficiently, helping businesses thrive in a competitive environment.

Recommended Products

C55 chain is a high quality, durable, and long lasting conveyor chain that is manufactured using high quality components.

CamelConvey C188 pintle chain variant is also available, providing additional options for specialized applications.

900 Class Pintle chain is primarily used in the palm oil industry and can withstand demanding applications.

400 Class Sugar Mill Pintle Chain is a lightweight, capable of handling average loads at slow or intermediate speeds.