Quality Policy

Our policy enforces high standards, quick issue resolution, continuous improvement, and team training, ensuring quality and timely delivery.

| Image | Roller Conveyor | Model | Description | More |

|---|---|---|---|---|

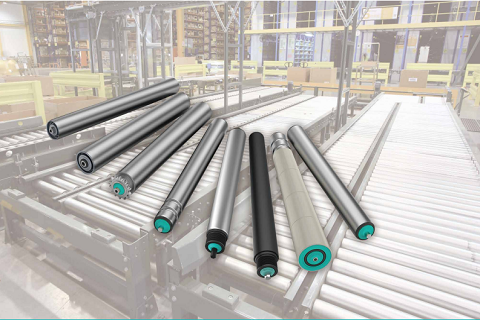

| Flexible Roller Conveyor | Roller conveyor | Motorized Roller Expandable Conveyor combines the efficiency of motorized rollers with the flexibility of an expandable design. | |

| Powered Flex Conveyor / FWDO-50-L800 | Roller conveyor | Motorized Roller Expandable Conveyor combines the efficiency of motorized rollers with the flexibility of an expandable design. |

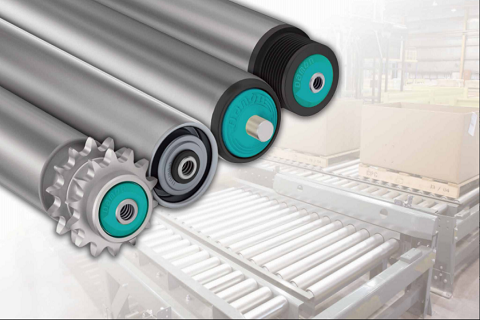

Conveyor rollers provide a smooth and consistent method of transporting items, enhancing workflow efficiency.

They can handle a wide range of products, from small packages to heavy pallets, across various industries.

Conveyor rollers are built to withstand heavy use and harsh industrial environments, ensuring long-term reliability.

The simple design of roller conveyors makes them easy to maintain and repair, reducing downtime and operational costs.

Our policy enforces high standards, quick issue resolution, continuous improvement, and team training, ensuring quality and timely delivery.

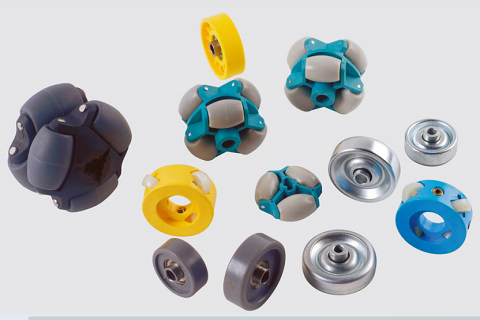

CamelConvey’s engineers rigorously test tensile strength and durability, consistently delivering long-lasting, high-quality chains.

CamelConvey offers end-to-end solutions, from OEM services to global partnerships, meeting unique customer needs effectively.

Our technical team ensures quality with on-site visual and data-driven inspections, focusing on precision in every product.