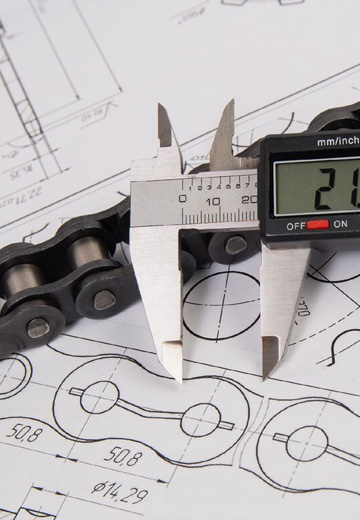

Durable Designs for Demanding Applications

At CamelConvey, our commitment to quality begins with our exceptional product engineering. When designing our conveyor systems, our primary focus isn't on finding the cheapest solution but on identifying the most suitable approach for the intended application. We recognize that our customers often face challenging conditions such as high temperatures, severe corrosion, and heavy loads. Therefore, our designs are tailored to consistently produce high-quality, durable products that not only meet but exceed these requirements.